Table of Contents

As technology evolves rapidly, confidence in product durability and performance is more vital than ever. The capability to replicate extreme and varied environments in a controlled setting is revolutionizing product testing—and this is where environmental test chambers come into play. Whether launching a new electronic device, designing automotive components, or researching pharmaceutical stability, utilizing an environmental chamber from Associated Environmental Systems can dramatically increase reliability. These devices help manufacturers expose products to simulated real-world conditions, preventing costly failures down the road and paving the way for safer, more innovative solutions.

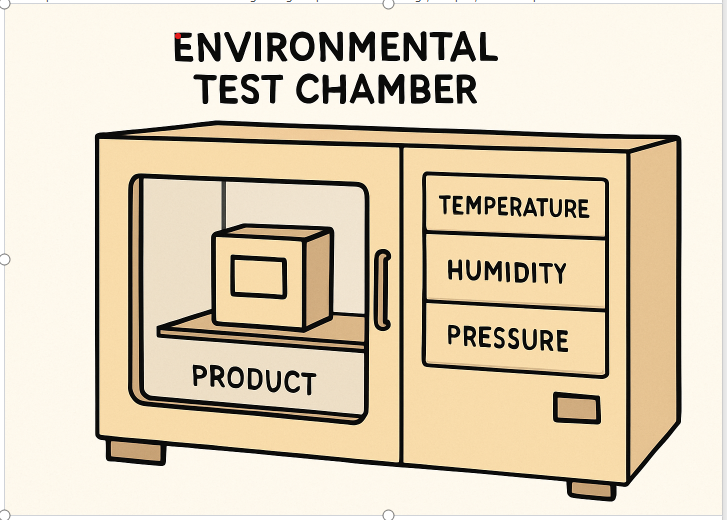

By controlling factors such as temperature, humidity, pressure, and vibration, environmental test chambers offer more than just compliance—they foster ingenuity and a competitive edge. Companies striving for minimal product recalls and extended warranties now turn to these chambers to optimize designs, enhance quality assurance, and comply with strict global regulations. Modern environmental chambers not only increase consumer confidence but also enable critical research across many fields, supporting long-term growth and trust in today's interconnected marketplace.

With sustainability and technological integration at the forefront, the role of environmental test chambers continues to expand. New features in these chambers help businesses meet environmental goals, reduce operational costs, and support the global shift toward greener manufacturing. They are instrumental in advancing R&D, contributing to more brilliant, safer products for end-users worldwide.

What Are Environmental Test Chambers?

Environmental test chambers are precision tools engineered to simulate a variety of natural and extreme environmental conditions. By manipulating climate parameters—temperature, humidity, air pressure, and even vibration—these chambers allow products, materials, or components to be evaluated under reproducible scenarios. As a result, manufacturers and researchers identify weaknesses, optimize material selection, and certify compliance with global standards before products reach the market.

Key Applications Across Industries

From automotive reliability to pharmaceutical stability, environmental chambers are at the heart of critical quality assurance programs:

Technological Advancements in Test Chambers

Modern environmental chambers feature advanced integration to address evolving R&D and manufacturing requirements. The adoption of IoT and AI-driven systems means tests are now programmable, remotely monitored, and automatically logged for audit purposes. Features such as real-time analytics and cloud connectivity allow teams to analyze test data instantly from anywhere, streamlining troubleshooting and speeding time-to-market.

Manufacturers are also developing modular designs, enabling labs to efficiently switch between a variety of tests using interchangeable inserts—resulting in time savings and budget flexibility. These advancements are making quality control more accessible and comprehensive than ever before.

Sustainability and Energy Efficiency

Manufacturers are increasingly mindful of environmental impacts and operational expenses. Modern test chambers emphasize energy efficiency by utilizing innovative materials, such as CFC-free refrigerants and halogen-free insulation. These improvements translate not only into a reduced carbon footprint but also into tangible energy savings of up to 18% compared to prior models. Such green engineering initiatives support both compliance with global standards and achievement of organizational sustainability goals.

Real-World Examples of Test Chamber Utilization

Choosing the Right Test Chamber for Your Needs

Conclusion

Environmental test chambers are reshaping how industries validate reliability, safety, and compliance in an increasingly competitive global market. Their versatile and evolving capabilities—now enhanced with technological and sustainability-driven advancements—position them at the heart of innovative product development, robust quality control, and groundbreaking research. As businesses embrace higher product standards, these test chambers will continue to enable innovation, efficiency, and dependability for years to come.

This post has been published by the admin of our website, responsible for content management, quality checks, and providing valuable information to our users.